Oil and gas sector can create one of the most dangerous work environments on Earth. Workers are exposed to the risk of events ranging from small equipment malfunctions to entire off shore rigs catching on fire. Fortunately, the application of machine learning in predictive asset maintenance can help prevent natural and human made catastrophes.

We have more information than ever on our equipment thanks to sensors and IoT devices, but we are still working on ways to process the data so it is valuable for preventing these catastrophic events. That’s where machine learning comes in. Data from multiple sources can be used to train a predictive model that helps oil and gas companies predict imminent disasters, enabling them to follow a proactive approach.

What is Predictive Asset Maintenance?

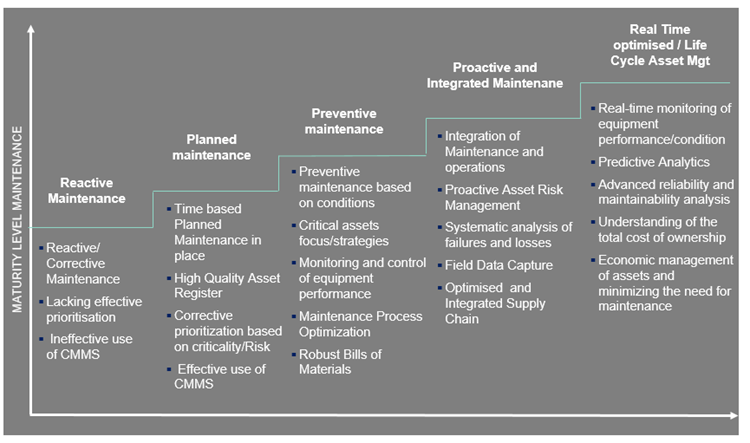

Predictive asset maintenance is a core element of the digital transformation of chemical plants. It is enabled by an abundance of cost-effective sensors, increased data processing, automation capabilities, and advances in predictive analytics. It involves converting information from both real-time and historical data into simple, accessible, and actionable insights. This is in order to enable the early detection and elimination of defects that would otherwise lead to malfunction. For example, by simply detecting an early defect in a seal that connects the pipes, we can prevent a potential failure that can result in a catastrophic collapse of the whole gas turbine.

Under the hood, predictive asset maintenance combines condition-based monitoring technologies, statistical process control, and equipment performance analysis to enable data from disparate sources across the plant to be visualized clearly and intuitively. This allows operations and equipment to be better monitored, processes to be optimized, better controlled, and energy management to be improved.

It is worth noting that the predictive analytics at the heart of this process do not tell the plant operators what will happen in the future with complete certainty. Instead, they forecast what is likely to happen in the future with an acceptable level of reliability. It can also provide “what-if” scenarios and an assessment of risks and opportunities.

The Challenge with Oil and Gas

Event prediction is one of the key elements in predictive asset maintenance. For most prediction problems there are enough examples of each pattern to create a model to identify them. Unfortunately, in certain industries like oil and gas where everything is geared towards avoiding failure, the sought-after examples of failure patterns are rare. Although there only exists a small number of failure examples, there exists a wealth of times series and inspection data that can be leveraged.

Operationalizing the Final Models

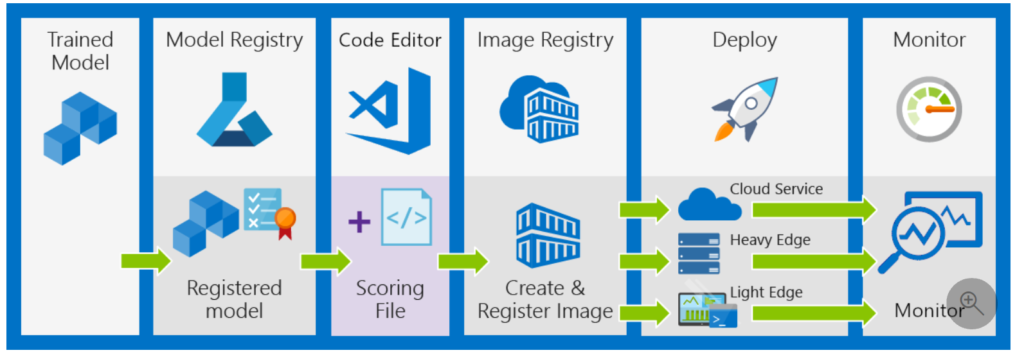

Scalability and operationalization are key design considerations from day one of the project, as the customers usually want to scale out the prototype to several other assets across the fleet. As a result, all components within the system architecture must be chosen with those criteria. In addition, the customers often want to have the ability to add more data sources. Cloud native tools can be used to streamline these requirements and deploy them in the production environment. The following diagram illustrates a common deployment workflow.

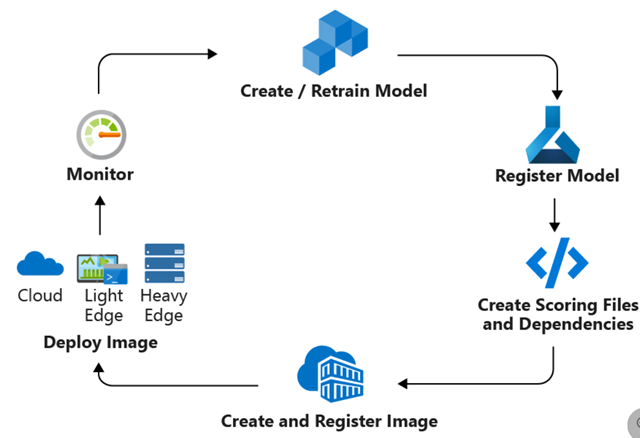

Also, the deployment model can be integrated into a Continuous Integration/Continuous Delivery (CI/CD) workflow as depicted below.

We are committed to bringing enterprise-grade AI advances to oil and gas industry using various languages, frameworks and development tools. Customers can easily our services into any part of their machine learning lifecycles to productionize their projects at scale, without getting locked into any one tool or platform.