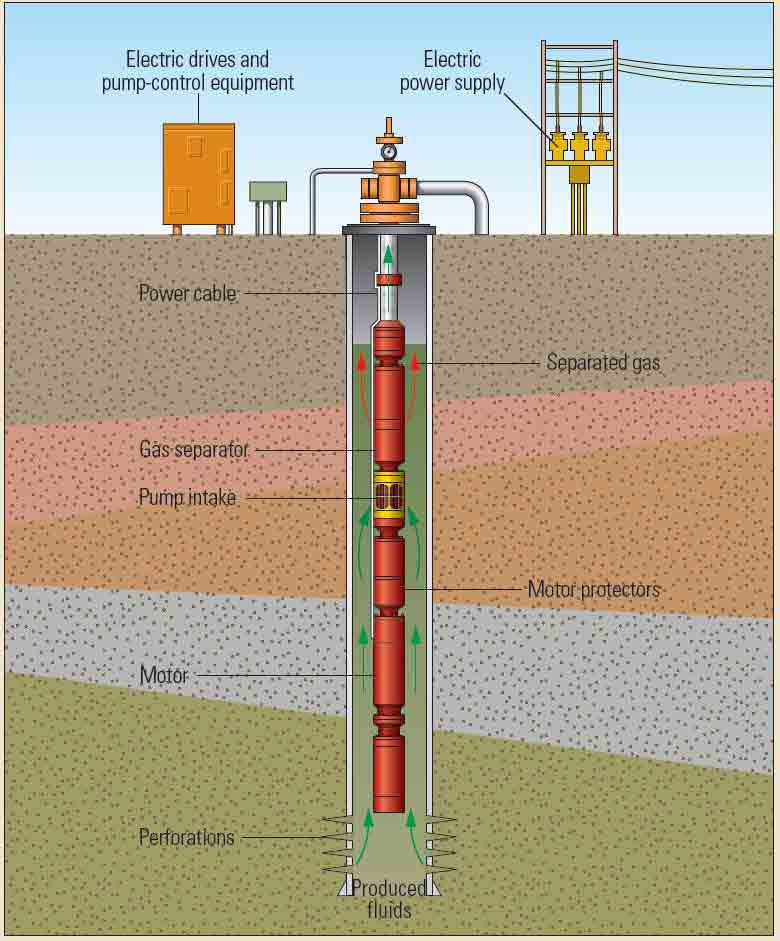

Artificial lifting methods are used to produce fluids from wells already dead or to increase the production rate from flowing wells; several lifting mechanisms are available to choose from. The importance of artificial lifting is clearly seen from the total number of installations: according to one estimate there are about 2 million oil wells worldwide of which about 50% are placed on some kind of artificial lift. One widely used type of artificial lift method uses an electrical submersible pump (ESP) set below the liquid level in the well to increase the pressure so as to overcome the pressure losses occurring along the flow path. During its long history, the ESP system proved to be an efficient means of producing liquid from oil and water wells.

Although ESPs are designed to work under extreme conditions such as corrosion, high temperatures and high pressure, their lifespan is much shorter than expected. ESP failures lead to production loss and increase the cost of replacement, because the cost of intervention work for ESP is much higher than for other artificial lift methods, especially for offshore wells. Therefore, the prediction of ESP failures is highly valuable in oil production and contributes a lot to the design, construction and operation of oil wells.

Recently, the trends of automation and digitalization, artificial intelligence (A.I.), and machine learning have gained momentum. Also, oil field digitization is considered a whole new opportunity for further production optimization in the oil and gas industry. The key question arises of how to implement these tools in such a way that all known risks are managed, value is genuinely delivered, and the actual results make a measurable difference to the profitability of the operation and, of course, that they are applicable to specified and predefined production optimization goals.

Beyond only creating a relation between continuous data, a data-driven model can be used to understand the internal relations between the parameters generating these data. Therefore, the key to perform fault detection on the ESP can be better defined as a problem to build an accurate datadriven model that describes the ESP system dynamics. We developed data-driven models based on machine learning algorithms that can predict downhole electrical submersible pump problems, so that proper actions might be taken proactively to avoid the occurrence of such problems. The approach of the supervised learning is used to train the model. This model will be able to predict the probability of some abnormal conditions or class label a few days before events.