Ever-present and dynamic uncertainty is intrinsic to modern‚ complex supply chains. Uncertainty continually challenges inventory decisions – the balancing of capital investment constraints and service-level goals. Despite 25+ years of software deployment from traditional vendors for inventory management and planning‚ it seems that the answer to an inventory analyst’s question: “how much” is as elusive today as it has always been.

In order to stay competitive in today’s world‚ organizations need to constantly reconfigure supply chains and continually manage the various types of ever-changing demand- and supply-side uncertainties. But intelligent decisions for managing these uncertainties rely on data in multiple‚ disparate on-premise or cloud source systems. Typically built and implemented a decade or two ago‚ these systems (e.g.‚ Material Requirements Planning‚ i.e.‚ MRP) are rule-based and rigid and thus incapable of handling large volumes of data distributed across various source systems.

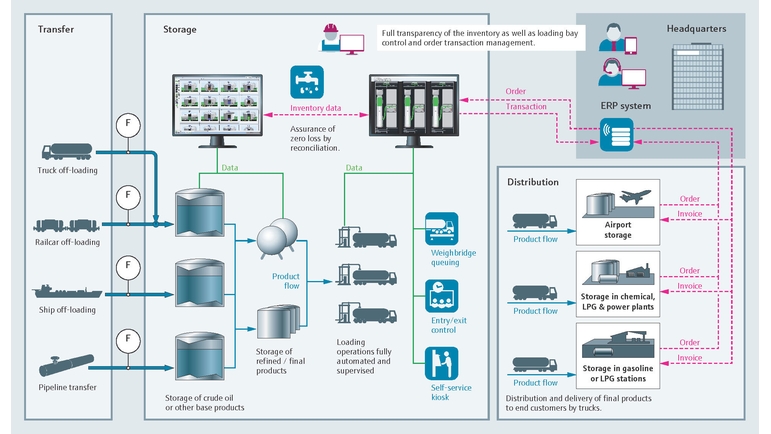

Solving these challenges requires adoption of a big data Artificial Intelligence (AI) platform able to aggregate data from multiple disparate source systems (e.g.‚ enterprise systems‚ IoT sensors‚ or 3rd party data providers) and apply AI techniques that learn continually from new data. The types of data useful for optimizing inventory include demand‚ supplier orders‚ production orders‚ bill of materials (time-varying)‚ change history of re-order parameters‚ and inventory movement data. Sophisticated AI techniques can make sense of the available data‚ determine optimal inventory levels‚ and provide actionable recommendations to the users‚ all in real-time.

Companies in industries typically lock up a significant part of their working capital in inventory. Average inventory typically subsumes 10% – 20% of a company’s revenue. A reduction in inventory by 20% – 25% through optimization will free up cash‚ ranging from 2% to 5% of revenue. This cash can be reinvested and increase shareholder value. To put things in perspective‚ a company with $1B in inventory can free up $33M to $83M in working capital by optimizing inventory on a big data AI platform.

The Challenge of Big Data

One of the prerequisites for using AI is the ability to aggregate all the necessary data from various disparate source systems such as MRP‚ Enterprise Resource Planning (ERP)‚ Asset Management‚ Supplier Management‚ and Inventory Planning. Many enterprises engage third-party service providers for data integration‚ and end up spending millions of dollars. Yet most of those projects fail. Others try data integration in-house‚ using open-source technologies‚ investing significant amounts of time and money‚ only to hit complexity hurdles. In order to apply AI at scale‚ enterprises instead need a platform that makes integration of data from multiple source systems easy and reliable.

Applying AI to Inventory Optimization

Once the prerequisite for data integration is successfully met‚ AI can be used to effectively and dynamically manage uncertainty‚ and systematically reduce inventory levels across all locations while minimizing the probability of stock-outs. Key elements of AI such as statistical modeling‚ machine learning‚ and optimization can be applied to inventory optimization.

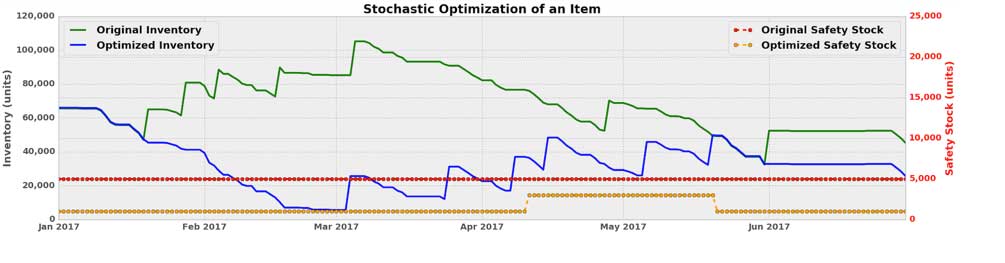

Manufacturers typically use rule-based systems to determine the timing and size of orders that need to be placed with suppliers. Static rules do not account for any variability‚ which leads to sub-optimal inventory levels. Inventory management can be formulated as a stochastic constrained optimization problem that solves for the optimal values of reorder parameters (e.g.‚ safety stock) that minimize the total landed cost (e.g.‚ inventory holding cost and shipping cost)‚ while maintaining a level of confidence (α) on the availability of items in stock‚ and satisfying other constraints reflecting the operational inner-workings of the facilities or factories‚ e.g.‚ concerning inventory management and ordering or replenishment policies. Notice that the confidence level is adjustable for each item (e.g.‚ 95%‚ 99% confidence)‚ providing the manufacturer control based on several factors such as cost of stock-outs and service-level agreements with their customers.

Within a stochastic optimization framework‚ at every day t‚ and for every part p‚ we solve an optimization problem based on our most recent estimation of probilistic characteristics of uncertainty. This approach enables us to jointly optimize the reorder parameters‚ the inventory levels for each part‚ and the arrival schedule from available suppliers.

Benefits of Inventory Optimization

Thanks to the intersection of today’s elastic cloud‚ big data and IoT technologies‚ combined with the application of powerful AI methods‚ organizations can now finally realize the promise and benefits of dynamic‚ adaptive inventory optimization. Using advanced AI techniques for inventory optimization can lead to:

- Reduction in inventory levels

- improve annual initial projected savings

- Additional savings due to fewer parts being ordered or ordering policies that balance holding vs shipping costs

- Increased productivity of inventory analysts by helping them focus on higher value tasks instead of tracking‚ managing‚ and auditing available inventory

- Uncover key helpful insights useful during negotiations with suppliers