In general, maintenance is defined as all technical and managerial actions taken during usage period to maintain or restore the required functionality of an asset or equipment. Predictive maintenance seeks to prevent equipment failure and downtime by connecting IoT-enabled enterprise assets, applying advanced analytics to the real-time data they deliver, and using the resultant insights to inform educated, cost-effective, and efficient maintenance protocols. Predictive maintenance allows businesses to anticipate failures and schedule maintenance when and where it’s immediately needed. It arms businesses with the information they need to push for peak performance from their valuable assets yet remain confident that they’re not pushing them too far and risking a costly breakdown.

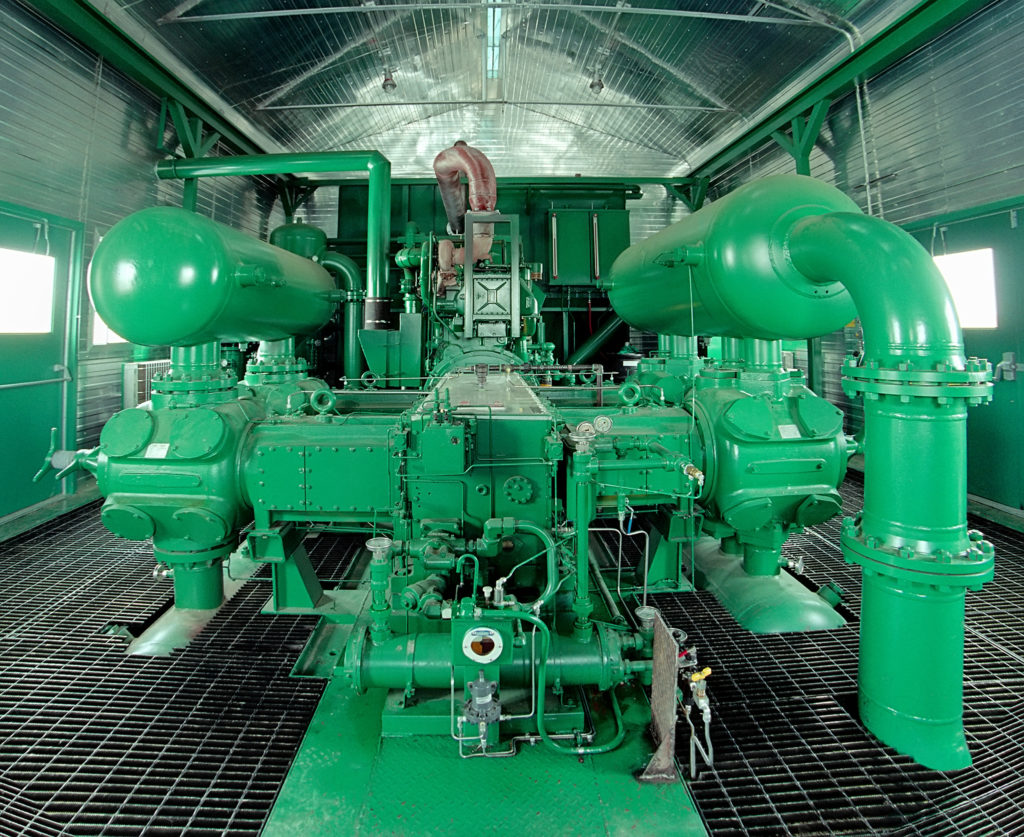

An LNG FPSO (Liquefied Natural Gas Floating Production Storage and Offloading vessel) is an offshore plant of delivering liquefied gas from a gas field to customers. Recently, the demand for LNG FPSO is highly increasing and the demand for LNG FPSO projects will grow along with the increased demand for natural gas [4]. The O&M phase of LNG FPSO requires heavy charges and more efforts to optimize the cost and to reduce the risks than the construction phase because of its long life cycle. Nowadays due to the fact that an accident of LNG FPSO in operation causes catastrophic damage, many studies have focused on a maintenance system. Predictive maintenance for the gas compressor equipments in LNG FPSO can provide offshore operation companies with a reference for doing the improved maintenance planning and decreasing equipment downtime due to unexpected failures.